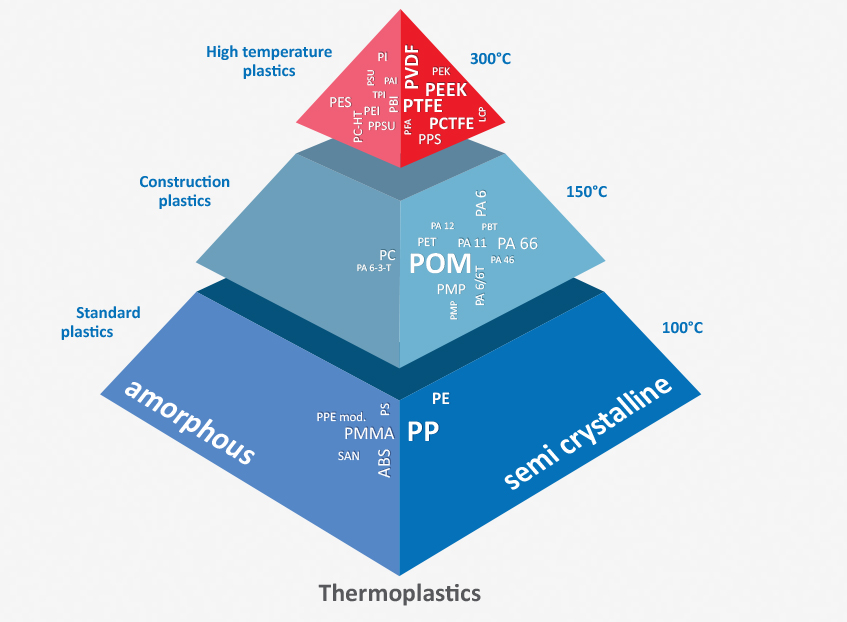

PTFE & PTFE Compounds

- extremely low coefficient of friction

- high chemical resistance

- high temperature resistance (up to 250°C)

POM & POM Compounds

- high toughness, hardness and stiffness

- high impact strength/resistance

- extremely high dimensional stability

PEEK & PEEK Compounds

- very high temperature resistance (up to 290°C)

- high mechanical strength and stiffness

PCTFE

- highest hardness and mechanical properties of all fluoropolymers

- dimensional stability

PVDF

- high mechanical properties

- high chemical resistance

Semifinished parts production

Pressing / Sintering

Granular PTFE and its compounds will be filled in a stamp, pressed and afterwards sintered. With this process step large billets can be made. These billets can be processed on a lathe, grinded or made to foils for further production steps.

RAM-Extrusion

Free flowing granular PTFE and its compounds are stepwised forced through a continues extruder-oven and sintered to an endless tube or rod. These rods or tubes can be processed on mechanical lathes.

Quality assurance

The production plants are certified according to highest quality standards exceeding the customers requirements.

Strict quality standards inside our production combined with advanced equipment guarantee high-end quality for our customers.

Raw materials, semifinished products and finished parts are monitored in our own material laboratory in Burscheid.

Material laboratory – Test methods

- Density and Moisture Measurements

- Deformation under Load

- Differential Scanning Calorimetry (DSC)

- Compression Set

- Microscopy

- Rebound Resilience

- Hardness Measurement (Shore A, Shore D)

- Durability Test

- Thermogravimetric Analysis (TGA)

- Tensile Strength / Elongation at Break