Seals

Seals – robust and wear-resistant

Sealing systems have become indispensable in modern everyday life. Wherever plants, machines, engines or piping systems are operated and media of gaseous, liquid or solid consistency have to be moved, sealing elements designed for the respective application are used.

Seals compensate for manufacturing tolerances in the functional compound of paired components, make the

They make the economical production of housings, containers, shafts, pipes and many other components possible in the first place.

In the wide range of possible applications, the most diverse temperature and pressure ranges must be taken into account.

Resistance to a large number of substances, some of them very aggressive, which are in direct contact with the sealing material, must be ensured over the entire specified product life.

Our application engineers will be happy to assist you in selecting the right combination of materials and sealing elements for your requirements profile.

If no suitable standard sealing element is available, customised moulded parts can also be created in a short time and in close coordination with our development department.

Overview of seals

Wipers

Wipers are used in sealing systems for pneumatic and hydraulic cylinders to prevent impurities from entering the cylinder interior.

Due to the tight fit in the groove as well as the elastic contact of the wiper lip on the rod, the wiper element prevents the entry of unwanted external media.

This prevents contamination of the hydraulic medium which could damage guides, seals and other components.

The Fietz Group offers a wide range of wipers. Specially developed for hydraulic cylinder applications, FiPur® materials have outstanding friction properties as well as exceptional wear resistance.

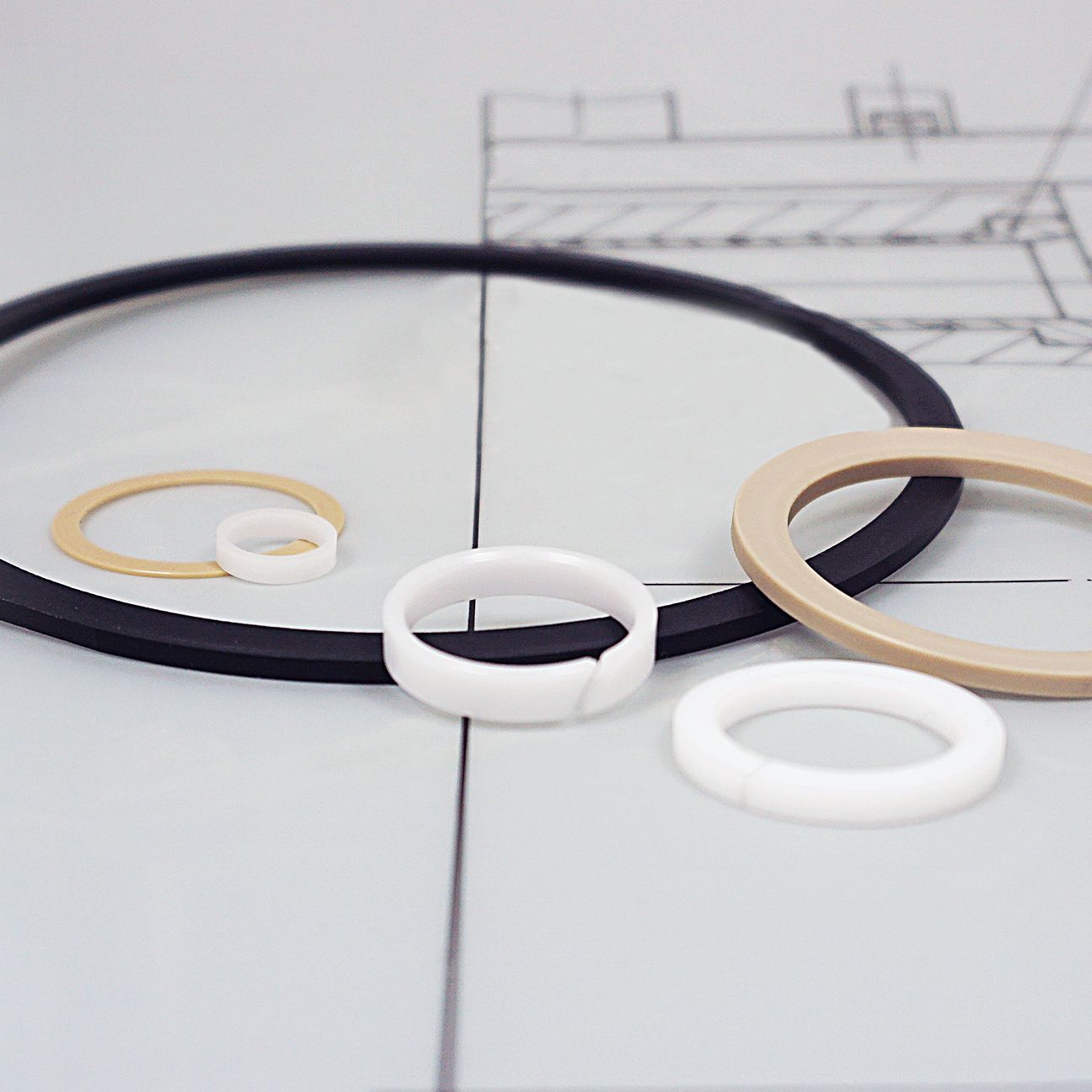

Ball valve seals

Ball valve seals made of PTFE, POM or PEEK are used to guarantee a sealing function with minimum friction.

Material properties:

POM is used when high dimensional stability is required.

PTFE is used for high temperatures, chemical resistance and food grade compliance.

PEEK is used for high pressure stability and high temperatures.

PTFE ball valve sealing rings are suitable for temperatures up to 220°C, have a low breakaway torque and are resistant to chemicals.

breakaway torque and are resistant to chemicals.

Ball valve sealing rings made of PEEK, on the other hand, are used when higher pressure resistances are

are required.

Coupling rings

You can obtain outer rings as internally sealing, double-acting rod outer rings and as externally sealing, double-acting piston outer rings for every rod and piston diameter as well as wipers.

Fietz O-rings are preferably used for sealing in stroke-shaped movements and have proven their worth especially in the hydraulic sector.

Depending on the choice of material, operating pressures up to max. 800 bar (80 MPa) - and even higher with static loads -, speeds up to max. 15 m/min. and temperatures between -54ºC and +200ºC can be achieved.

An application with rotating or helical movement is only possible to a limited extent. Fietz shell rings are available in various material combinations, the properties of which are optimised for special areas of application.

Advantages of the Fietz shell rings

- High abrasion resistance

- Excellent sliding properties

- No stick-slip effect

- Several times longer service life compared to conventional seals

- Universally applicable for almost all lubricating and non-lubricating media

- Optimised material combination for special applications

- One-piece piston and cylinder head possible

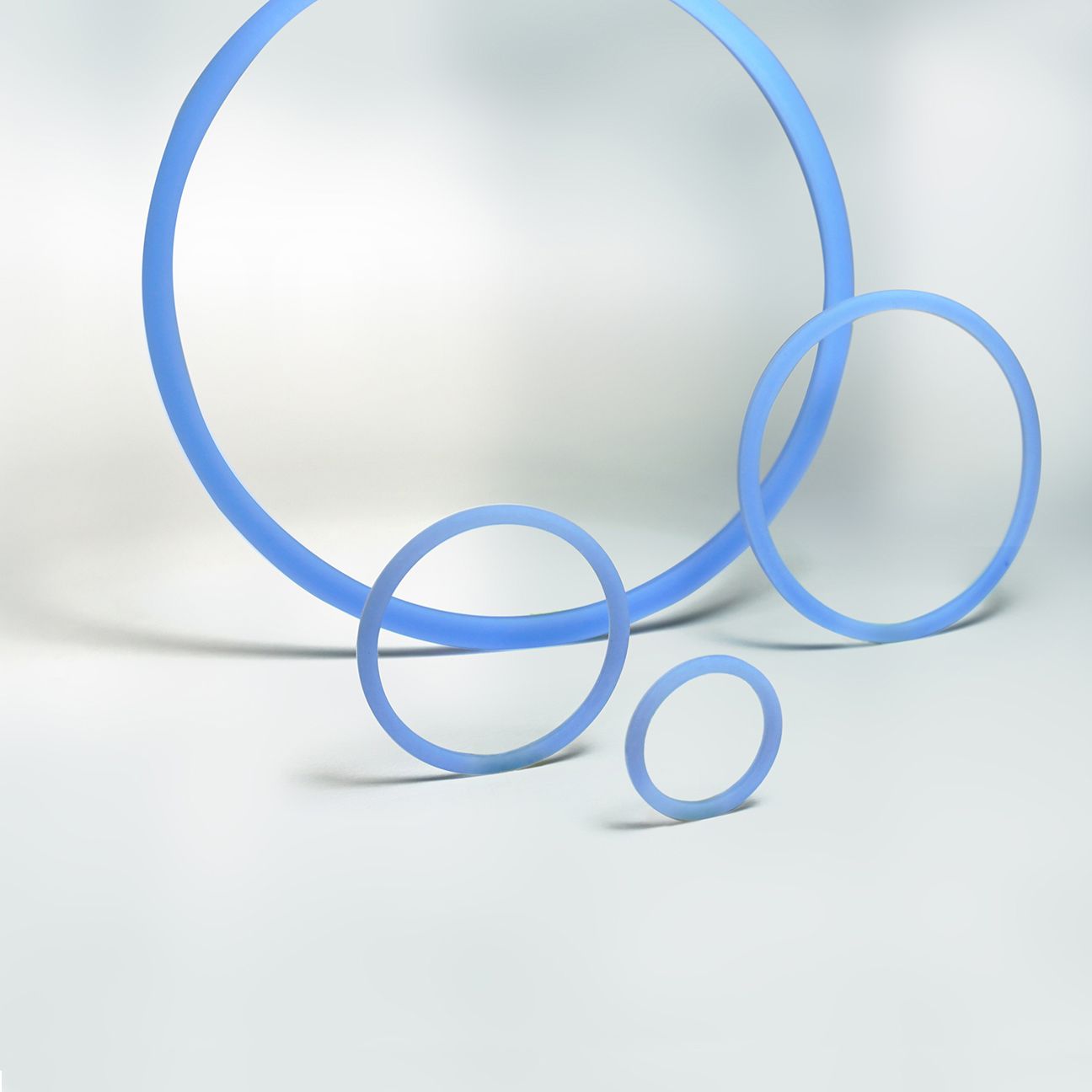

O-rings

O-rings in normal or quenched design in over 200 sizes from 0.6 mm inner diameter to 500 mm outer diameter in any cord size.

Solid O-rings made of pure or modified PTFE are used for static sealing of aggressive or hot media and are used wherever elastomer O-rings behave critically or fail completely. The excellent chemical and physical properties of PTFE materials guarantee long-lasting and maintenance-free function, even under extreme conditions.

PTFE O-rings are also used as sealing elements for slow movements. Here they offer the advantage of low friction losses due to the non-existent stick-slip effect.

In the above-mentioned applications and in the case of large temperature differences, it should be noted that the considerably lower elasticity of the PTFE O-ring compared to elastomer O-rings must be compensated for by additional mechanical contact pressure. The prerequisite for this is that the O-ring is well chambered in order to prevent the material-related tendency to cold flow.

An increase in elasticity can be achieved by thermal/chemical post-treatment (quenching) or constructive measures (design with grooves in the circumferential direction), whereby different types are available for the latter design depending on the application.

Materials

O-rings from Fietz are made of pure PTFE as standard. For special applications, the material can be modified with fillers to optimise certain properties.

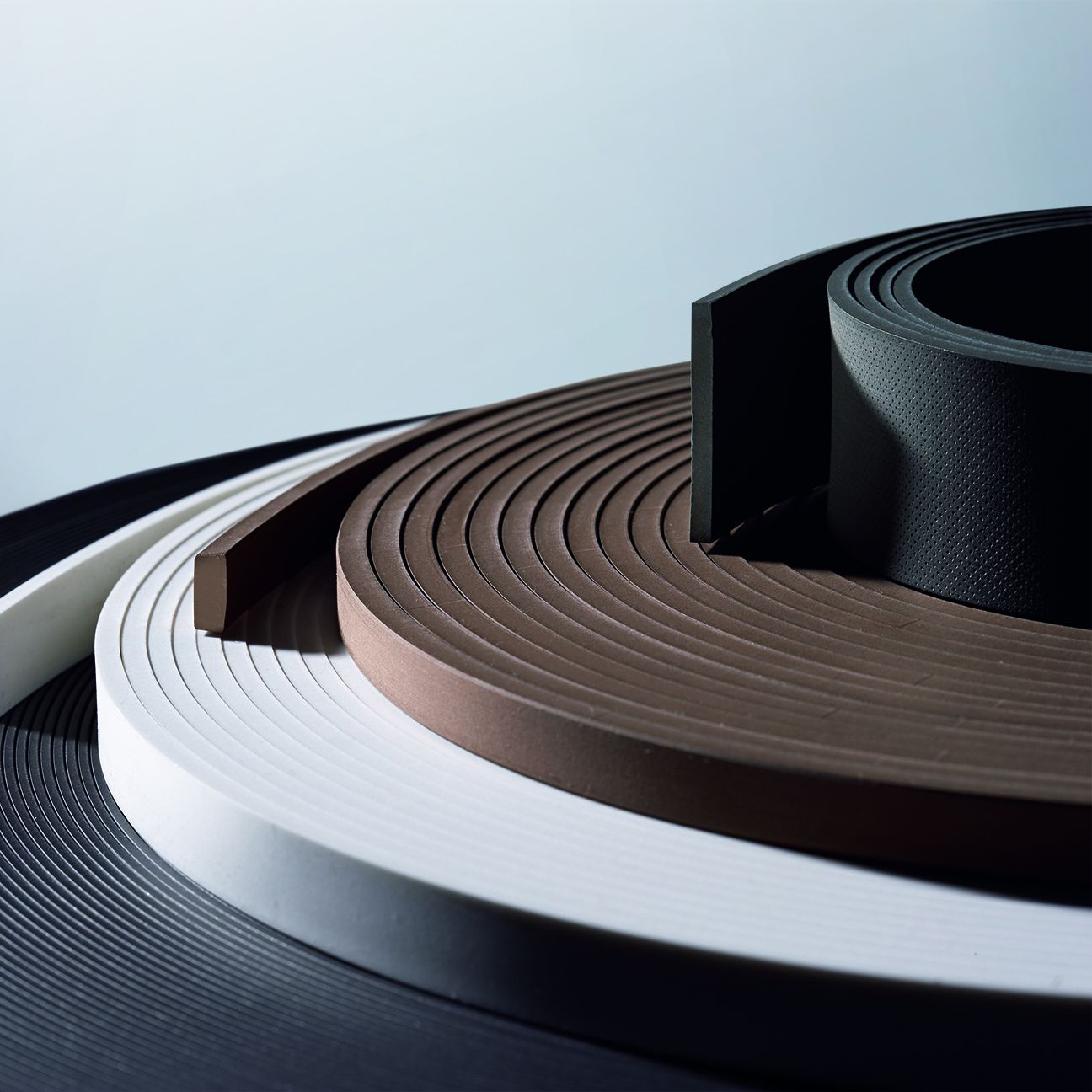

Polyurethan seals

Polyurethane seals - robust and wear-resistant

Fietz (FiPur®) offers manufacturers of fluid power components a range of tailor-made materials and suitable sealing geometries designed for the specific applications of this market.

Advantages of FiPur® seals

- High abrasion resistance, lowest wear values

- Very good pressure resistance (up to 400 bar)

- Very low permanent deformation

- Good dynamic properties: higher safety against leakage

- Sustainable solutions: through reduced maintenance costs, improved environmental protection and more favourable plant availability

- FiPur® materials are tailor-made for optimal installation conditions

- FiPur® polyurethane seals have the best prerequisites for problem-free snapping into the given installation spaces

www.fipur.de

Composite seals

Stepped rings as single-acting, internally sealing rod stepped rings and as externally sealing piston stepped rings for any rod and piston diameter.

Fietz step rings are preferably used for sealing in stroke-like movements and have proven themselves especially in the hydraulic sector.

Depending on the choice of material, operating pressures up to max. 800 bar (80 MPa) - and even higher with static loads -, speeds up to max. 15 m/min. and temperatures between -54ºC and + 200ºC can be achieved.

An application with rotating or helical movement is only possible to a limited extent. Step rings from Fietz are available in various material combinations, the properties of which are optimised for special areas of application.

Advantages of Fietz step rings

- High abrasion resistance

- Excellent sliding properties

- No stick-slip effect

- Several times longer service life compared to conventional seals

- Universally applicable for almost all lubricating and non-lubricating media

- Optimised material combination for special applications

- One-piece piston and cylinder head possible