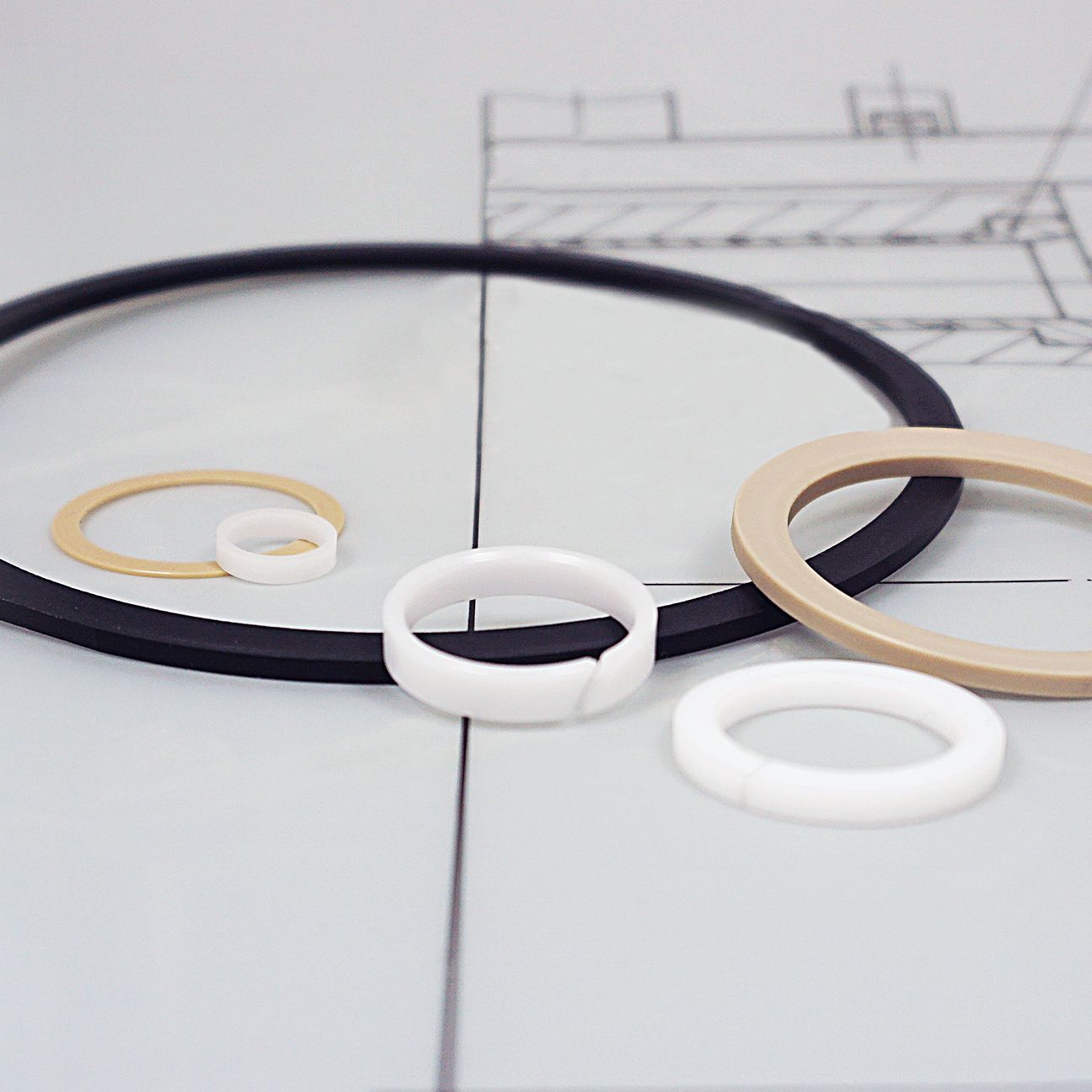

Products

Fietz Poroflon® Membrane filters

Filter and pressure compensation element

Vehicle batteries in electric cars require a pressure or degassing exchange. The pressure compensation element is made of porous PTFE.

Other applications can be found in various areas, such as in radar sensors in control units or for separating chemical media.

Manufacture

Porous PTFE is produced in a pressing and sintering process. The porosity is created by a combination of pressure and tempering processes (sintering).

Subsequent mechanical processing of the semi-finished product produces the desired geometry, e.g. a flat disk with a filter function.

Pressing > Sintering > Mechanical processing

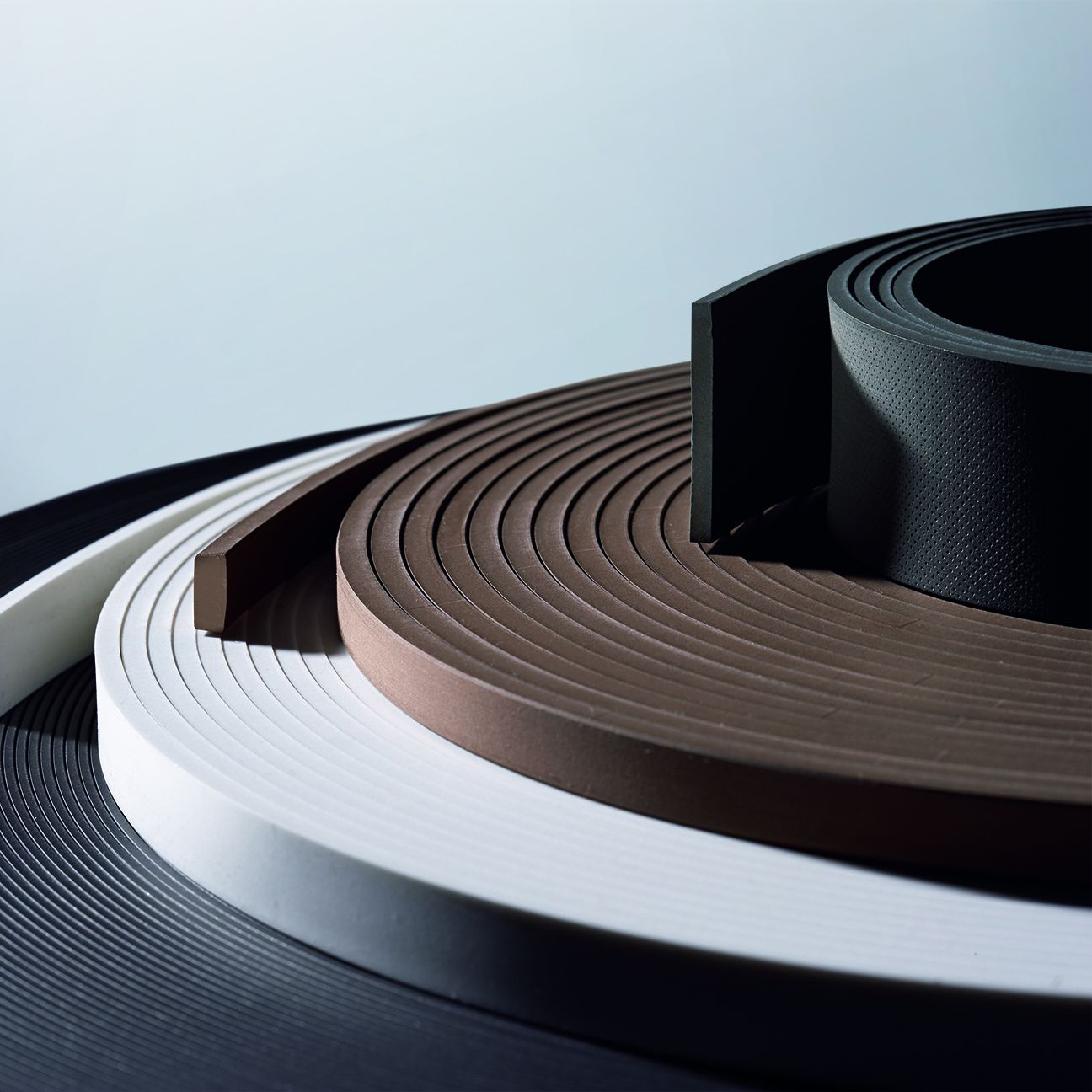

Porosity

Porous PTFE can be produced in different densities. The porosity determines the flow rates.

Example:

Use/properties

• Battery ventilation and pressure compensation

• Ventilation

• Separation of chemical substances

• Chemical and UV-resistant

• No release of trace elements to the filtrate (without additives)

• Anti-adhesive

• Hydrophobic

• Wide application temperature range -200° to over +260°C

• Optical reflectivity

• Dielectric behavior

Fietz Poroflon® is a registered trademark of Fietz Group.